BACKGROUND

Project Overview: The Design Office project spanned four weeks, featuring collaboration among students from different years of HiOA's Product Design program. Our group embarked on redesigning aluminum-tube packaging for products like caviar and mayonnaise.

Key Findings and Proposition: Based on user feedback, we identified issues with incomplete emptying and lack of preparation for recycling in the original packaging. Opting for environmental sustainability, we proposed replacing aluminum with paper, acknowledging the trade-off of reduced shelf life. To mitigate this, we suggested smaller portion sizes and marketed the new design as a fresh product.

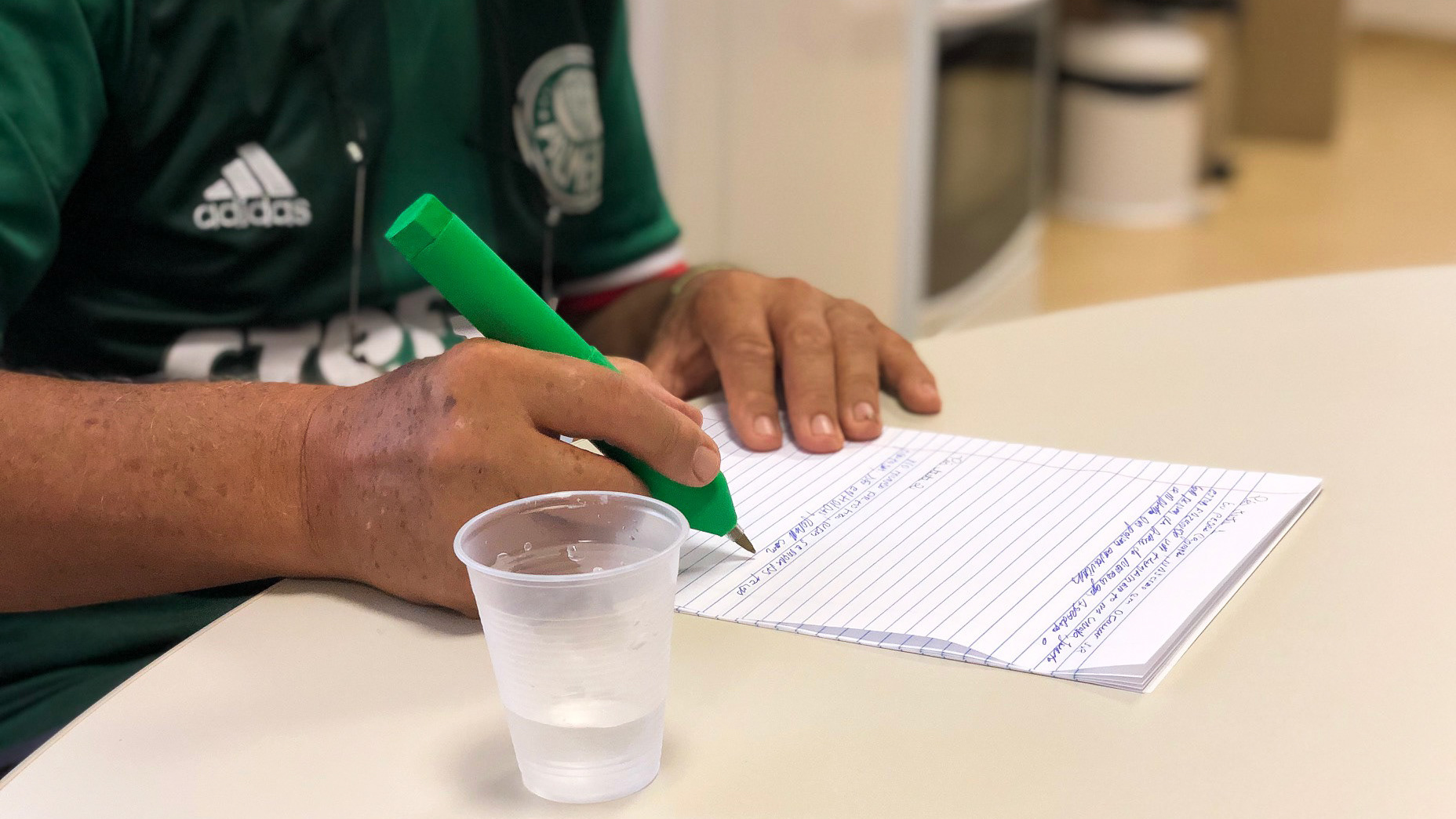

Design Approach: We focused on user-centric design methods, including ethnographic research, packaging analysis, and interviews. This led us to prioritize customer values—convenience, visual appearance, and effective food preservation. Our "design musts" included using fiber/wood-based materials, ensuring user-friendly packaging, and reducing/eliminating food waste. To learn more about the options regarding packaging, we also visited a Teta-Pak factory in Sweden, and gained valuable information about the different possibilities in paper-packaging which influenced our design choices.

GOAL:

to design packaging that can address user concerns, improve sustainability, reduce food waste

DURATION:

2 months, spring 2018

PARTNERS:

Norgesgruppen AS, OsloMet

PROJECT MANAGERS:

Briar Gill, Kasper Jakobsen, Juan David Sanchez Renteria

DESIGNERS:

Egle Juodziukynaite, Gabriel Arne Hofstra, Ingunn Skirstad, Marthine Fredrikke Spinnangr, Anne Bjørklund Skomdal, Oscar Frank, Oda L Benediktsson, Joakim M. Winum

CONCEPT 1

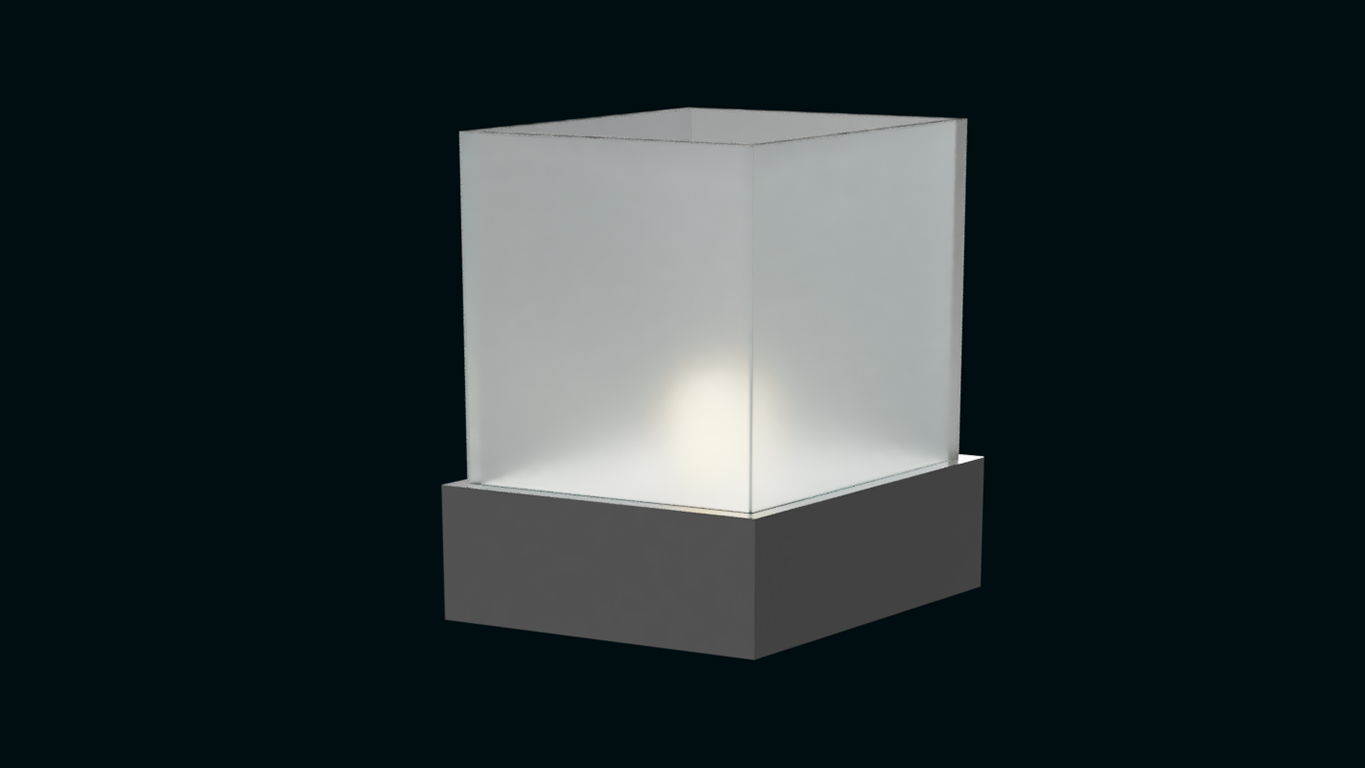

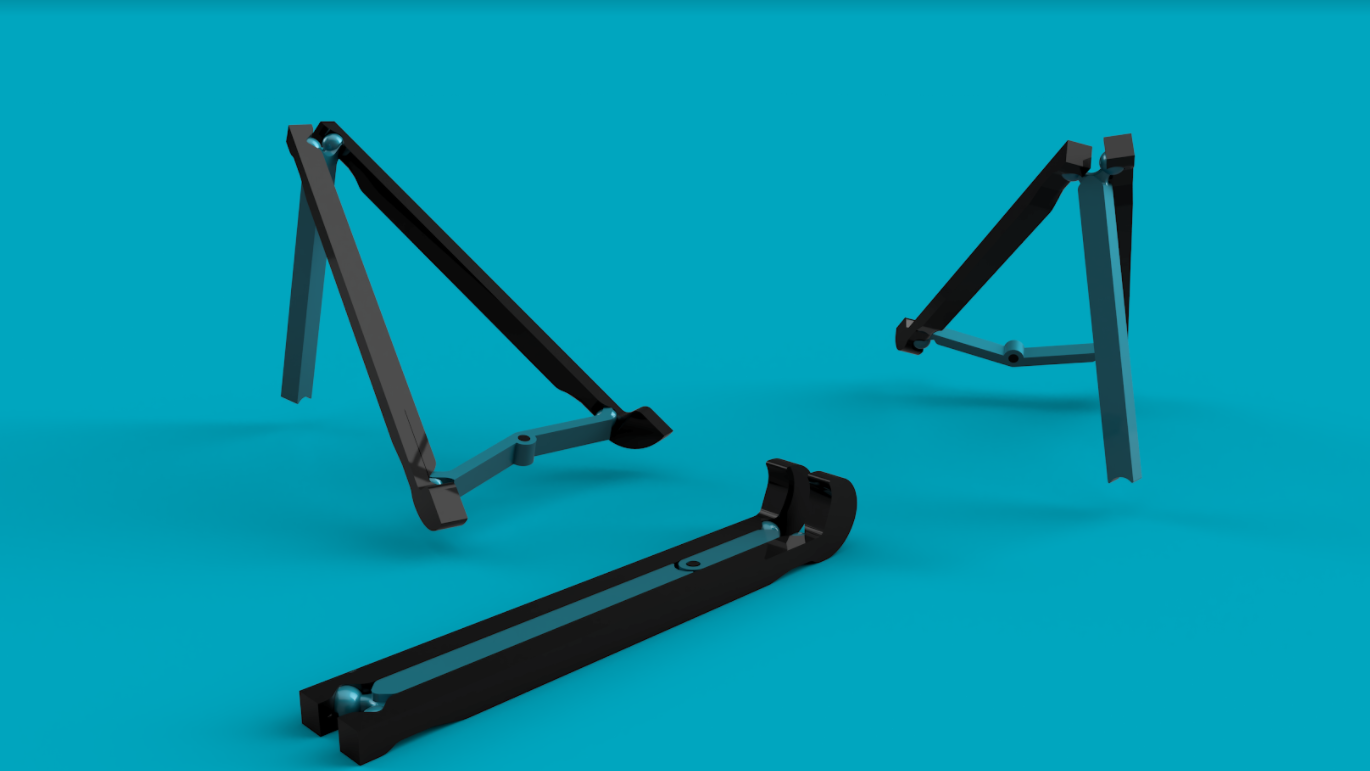

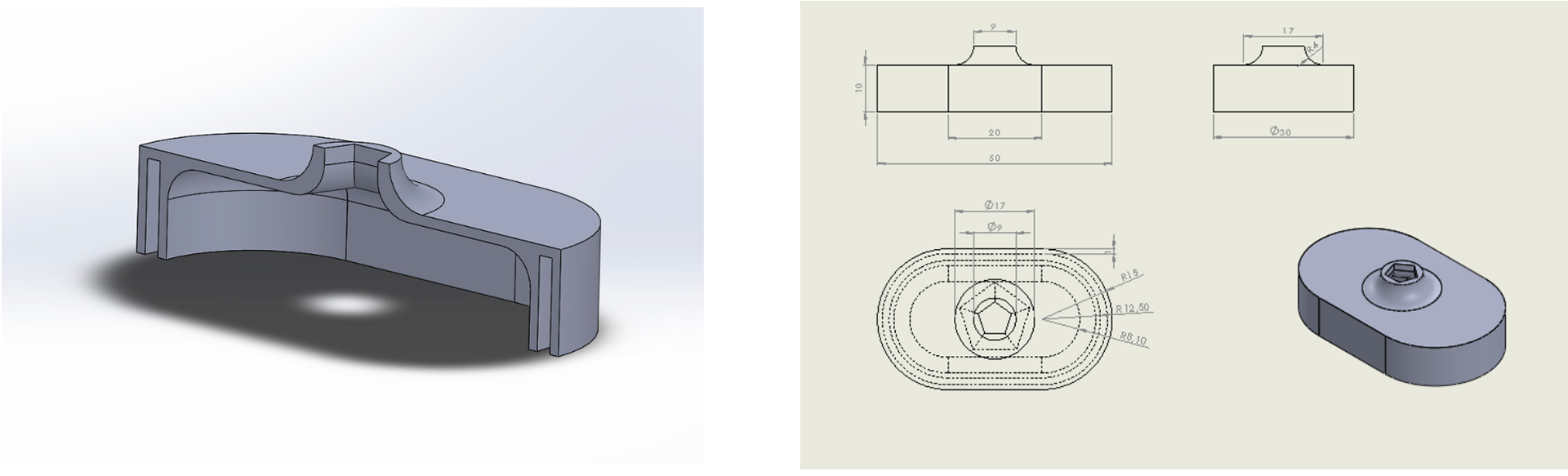

Our focus was on preventing food residue build-up in the aluminum tube neck. Our redesign allows users to easily remove remaining food by ripping off the cap with a knife or spoon. We aim for a mono-material design but prioritize easy recycling, even if a plastic cap is used to extend shelf life. Considering user ergonomics, we introduced a diamond shape to guide food towards the cap intuitively, and the oval lid shape reflects the material's response to compression. To address potential premature tearing, we added a support wall where the tube and cap meet, requiring further testing.

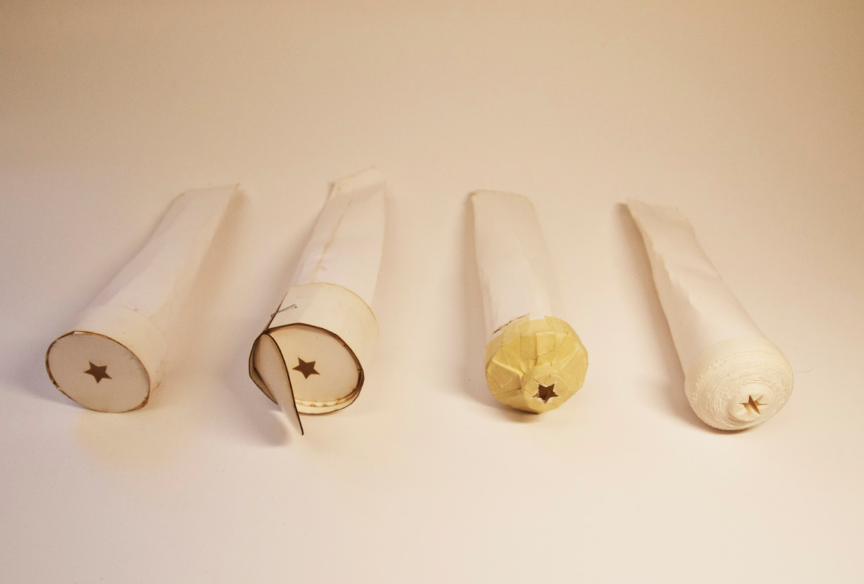

PROTOTYPES

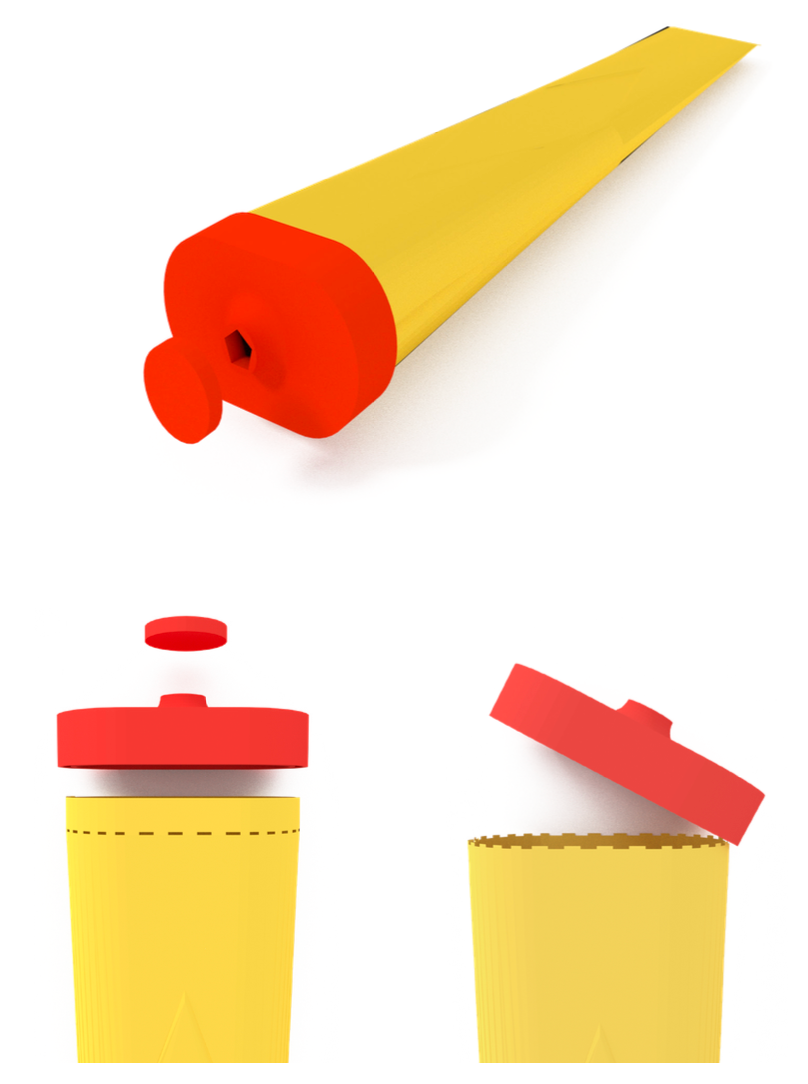

CONCEPT 2

The objective of this design is to ensure the user can empty all content while in use. Then once finished one can simply pull tabs to open entire container allowing user to access remaining food. The added benefit of this is the separation of materials for recycling. The final result is a form that is as flat as the paper it was made from. Again assisting for recycling. Because we are working with a fiber based material, the packaging has been given focused creases giving the tube a smooth look in stores and when used.

We acknowledge problem areas such as manufacturing limitations, the connection between two materials, expiration date/shelf life, and the property of the material itself. With further exploration we would be interested in working together to solve these.